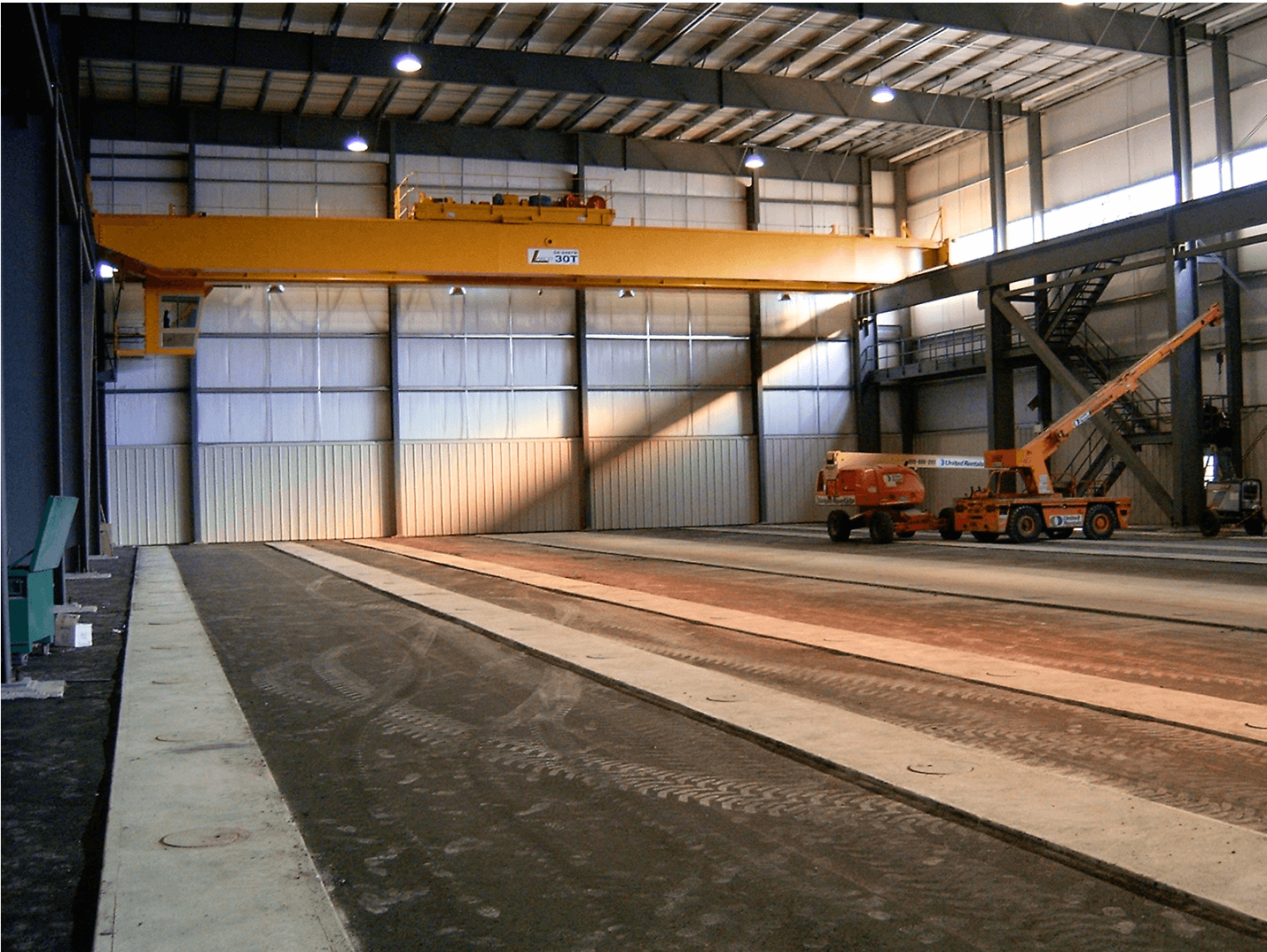

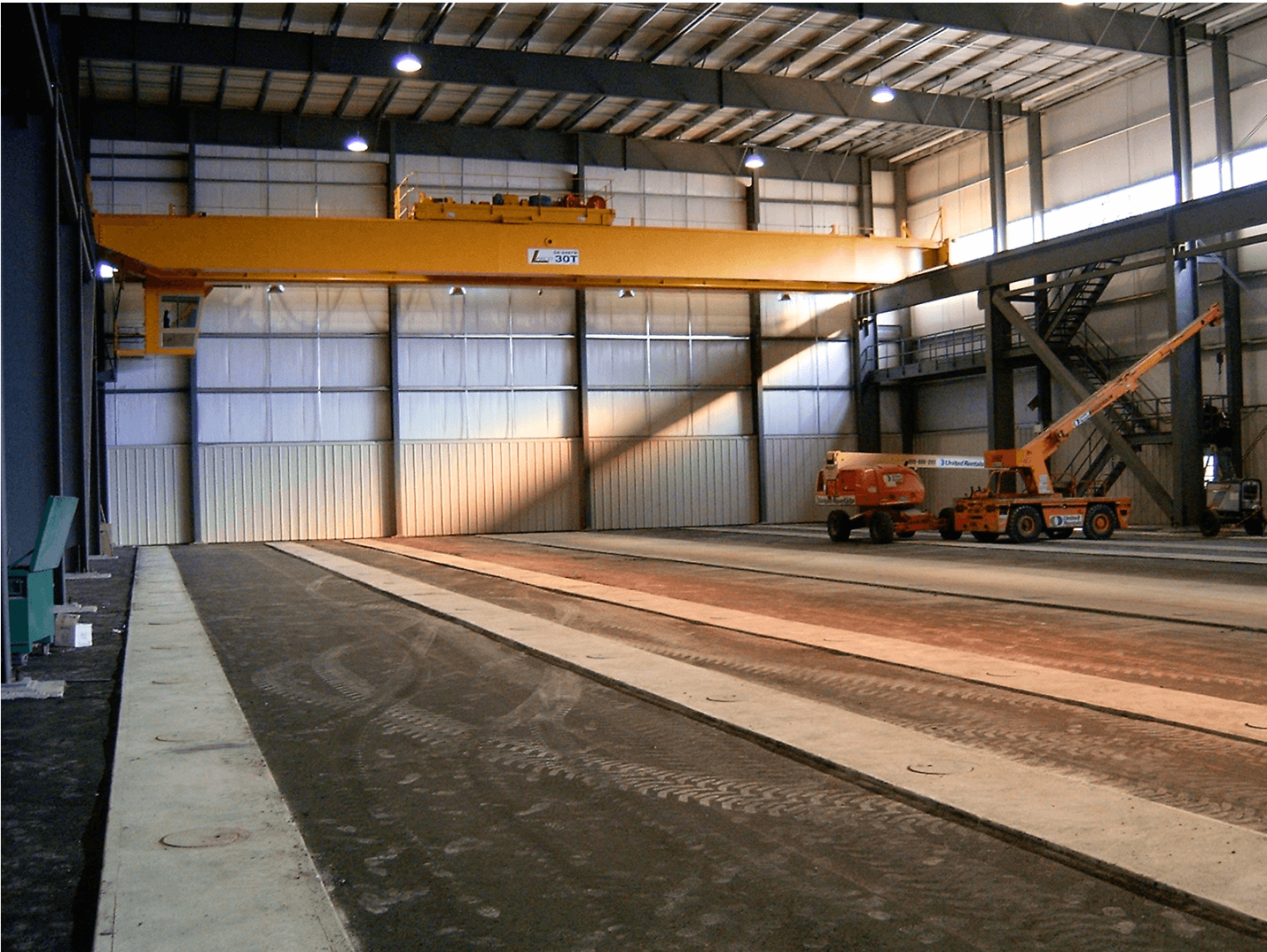

Pre Engineered Metal Building Wall With Continuous Insulation

Insulation Options in Metal Buildings (Part 2)

Posted on September 13, 2017 by Ceco Building Systems

In our last blog post, we clarified the different ways to show compliance with energy codes—namely, prescriptive envelope trade-offs with COMcheck, or full computer modeling. For purposes of this post, let's assume that we are going to use the envelope trade-off method to create an energy-compliant metal building while seeking to control construction costs.

Here are the steps to follow:

1. Determine Governing Code: Different jurisdictions (cities, counties, states) typically adopt different versions of national codes, such as the International Energy Conservation Code (IECC) or ASHRAE 90.1. Check with the local authority to determine which code(s) and which publication year(s) apply to your building. You can also see a listing on websites like www.energycodes.gov or http://bcapcodes.org/code-status/state/. Note that many places will allow the choice of an adopted version of the IECC OR ASHRAE 90.1 to show compliance; however, they cannot be interchanged. Only one or the other can be selected for the entire building to show compliance.

2. Determine Climate Zone: Both the IECC and ASHRAE 90.1 use the same definition of eight basic climate zones (listed by counties across the United States) to define prescriptive building requirements for components such as insulation. Hence, you need to identify the climate zone corresponding to your building location in order to find the proper information in the rest of the energy code.

3. Identify Prescriptive Envelope Requirements: Look up the prescribed requirements for walls, roofs, and floors specifically for metal buildings in the selected energy code based on the appropriate climate zone. This will provide a starting point for determining how easy or challenging it might be to achieve those levels for your building.

4. Make Construction Method Choices: Consider other alternatives in construction methodology. For example, would standard batt insulation in the walls be easier to install than adding what the code refers to as continuous insulation (ci)? This requirement for ci is usually met with rigid foam insulation installed outside of the metal structural components and under metal roofing or siding. Consider a few scenarios that make sense from a construction and cost-efficiency standpoint.

5. Run COMcheck: Take each identified construction scenario and put the relevant information into COMcheck, the free computer software commonly used to show energy code compliance. It is simpleto use once basic wall, roof, window, door, and floor areas are identified, along with the corresponding R-values or U-factors for each. Once the first one is completed, it can be saved and a copy made to compare it with a different scenario of insulation levels or other details. Going forward in this way, multiple options can be assessed pretty quickly and easily to see which ones meet or exceed code—and which ones don't.

6. Compare Costs: Once the different options are identified that meet the energy code, you can compare the known material and labor costs of the different options to determine which makes the most sense. See the example below.

Example Metal Building Project:

Size: 60x100x20 with 1-1/2:12 pitched roof

Climate Zone: 2

Scenario 1 (based on prescriptive code requirements):

Roof: R-30 Liner System

Walls: R-13 faced insulation PLUS R-6.5 continuous insulation

In this scenario, the roofing liner system is fairly straightforward to install, but the requirement for continuous insulation in the wall requires more material and labor cost.

Total estimated insulation cost: $16,902

Scenario 2 (proposed design alternative run in COMcheck)

Roof: R-36 Liner System

Walls: R-19 faced insulation

In this scenario, the amount of insulation in the roof is increased and the wall insulation is consolidated into one installation.

Total estimated insulation cost: $10,045

Result: Both scenarios are shown to be compliant with the energy code, but scenario 2 reduces the installed insulation cost by $6,857, or 40 percent. (Note that this is an example only for the specific conditions noted. Actual results will vary, of course, with different buildings, different materials, and different locations.)

To learn more about different ways to insulate metal buildings effectively, see http://www.mbma.com or https://www.cecobuildings.com.

Content for this article was provided by Kyle Smige, District Manager at Therm-All. Therm-All is a pre-engineered metal building insulation laminator that provides an assortment of product lines and accessories, exceptional customer service, and energy code compliance consultation.

In our last blog post, we clarified the different ways to show compliance with energy codes—namely, prescriptive envelope trade-offs with COMcheck, or full computer modeling. For purposes of this post, let's assume that we are going to use the envelope trade-off method to create an energy-compliant metal building while seeking to control construction costs.

Here are the steps to follow:

1. Determine Governing Code: Different jurisdictions (cities, counties, states) typically adopt different versions of national codes, such as the International Energy Conservation Code (IECC) or ASHRAE 90.1. Check with the local authority to determine which code(s) and which publication year(s) apply to your building. You can also see a listing on websites like www.energycodes.gov or http://bcapcodes.org/code-status/state/. Note that many places will allow the choice of an adopted version of the IECC OR ASHRAE 90.1 to show compliance; however, they cannot be interchanged. Only one or the other can be selected for the entire building to show compliance.

2. Determine Climate Zone: Both the IECC and ASHRAE 90.1 use the same definition of eight basic climate zones (listed by counties across the United States) to define prescriptive building requirements for components such as insulation. Hence, you need to identify the climate zone corresponding to your building location in order to find the proper information in the rest of the energy code.

3. Identify Prescriptive Envelope Requirements: Look up the prescribed requirements for walls, roofs, and floors specifically for metal buildings in the selected energy code based on the appropriate climate zone. This will provide a starting point for determining how easy or challenging it might be to achieve those levels for your building.

4. Make Construction Method Choices: Consider other alternatives in construction methodology. For example, would standard batt insulation in the walls be easier to install than adding what the code refers to as continuous insulation (ci)? This requirement for ci is usually met with rigid foam insulation installed outside of the metal structural components and under metal roofing or siding. Consider a few scenarios that make sense from a construction and cost-efficiency standpoint.

5. Run COMcheck: Take each identified construction scenario and put the relevant information into COMcheck, the free computer software commonly used to show energy code compliance. It is simpleto use once basic wall, roof, window, door, and floor areas are identified, along with the corresponding R-values or U-factors for each. Once the first one is completed, it can be saved and a copy made to compare it with a different scenario of insulation levels or other details. Going forward in this way, multiple options can be assessed pretty quickly and easily to see which ones meet or exceed code—and which ones don't.

6. Compare Costs: Once the different options are identified that meet the energy code, you can compare the known material and labor costs of the different options to determine which makes the most sense. See the example below.

Example Metal Building Project:

Size: 60x100x20 with 1-1/2:12 pitched roof

Climate Zone: 2

Scenario 1 (based on prescriptive code requirements):

Roof: R-30 Liner System

Walls: R-13 faced insulation PLUS R-6.5 continuous insulation

In this scenario, the roofing liner system is fairly straightforward to install, but the requirement for continuous insulation in the wall requires more material and labor cost.

Total estimated insulation cost: $16,902

Scenario 2 (proposed design alternative run in COMcheck)

Roof: R-36 Liner System

Walls: R-19 faced insulation

In this scenario, the amount of insulation in the roof is increased and the wall insulation is consolidated into one installation.

Total estimated insulation cost: $10,045

Result: Both scenarios are shown to be compliant with the energy code, but scenario 2 reduces the installed insulation cost by $6,857, or 40 percent. (Note that this is an example only for the specific conditions noted. Actual results will vary, of course, with different buildings, different materials, and different locations.)

To learn more about different ways to insulate metal buildings effectively, see http://www.mbma.com or https://www.cecobuildings.com.

Content for this article was provided by Kyle Smige, District Manager at Therm-All. Therm-All is a pre-engineered metal building insulation laminator that provides an assortment of product lines and accessories, exceptional customer service, and energy code compliance consultation.

Source: https://www.cecobuildings.com/blog/metal-buildings-insulation-options-part2/

0 Response to "Pre Engineered Metal Building Wall With Continuous Insulation"

Post a Comment